Commercial Kitchen Extraction System in Birmingham | Installation Guide, Standards, and Maintenance

You may also be wondering where to find a Commercial Kitchen Extraction System in Birmingham? In the industrial and always busy city of Birmingham, one of the most essential needs of any restaurant, fast-food outlet, café, hotel, or food-production unit is having a powerful, compliant, and properly designed air extraction system. Without such a system, a kitchen quickly turns into a hot, polluted, smoky, and hazardous environment. That’s why installing a hood and ventilation system is not just an optional feature, but a legal and hygienic requirement for any food-related business in the UK.

In this article, we provide a comprehensive and practical look at commercial kitchen extraction systems — from benefits and regulations to costs, maintenance, and key points to consider when choosing the right setup.

Why Is a Commercial Kitchen Extraction System in Birmingham Essential?

1) Preventing the Build-up of Grease and Contamination :

In commercial kitchens, smoke and grease produced during cooking spread through the air within minutes, and if these pollutants are not extracted, they settle on walls, ceilings, ducts, and even equipment. This significantly increases the risk of fire, creates unpleasant odours, damages equipment, and raises maintenance costs.

2) Complying with Birmingham’s Strict Health and Safety Regulations :

Birmingham and the wider UK enforce precise standards for commercial kitchen ventilation. If your system is not compliant, you may face fines, business licence suspension, inspection failures, and in case of an incident, the insurance company may refuse to cover the damages.

3) Reducing Temperature and Improving Work Efficiency :

Commercial kitchens naturally reach high temperatures, and without proper extraction, heat levels can rise to 30–40°C. This leads to severe staff fatigue, slower workflow, more mistakes, and reduced food quality.

Main Components of a Commercial Kitchen Extraction System

Hood :

The stainless-steel hood is the most important part of the extraction system. It must be professionally welded, made from 304 or 430 stainless steel, and the filters should be washable.

Grease Filter :

Filters are responsible for removing grease and vapour. You can read a full explanation in the article The Importance of Using High-Quality Grease Filter in Ventilation Systems

Ducting :

Air-transfer ducts should be made from galvanised steel or stainless steel. The route must be straight, short, and with minimum bends to avoid air pressure loss.

For learning about different types of restaurant hoods, visit: Shop

Installation Standards for Extraction Systems in Birmingham

Installing such systems must comply with Birmingham’s local health and safety regulations. If you need a professional company, click the link here: About-Us

Important Standards :

- Ducting must be made from galvanised sheets with standard thickness.

- The fan must be selected according to the size of the kitchen.

- Filters must be washable.

- The duct route must be short and straight.

How Are Extraction Systems Installed?

Step 1: Site Inspection

A specialist must first thoroughly assess the kitchen layout.

Step 2: Ductwork Design

The duct path is designed based on the location of the cookers and the best possible exhaust outlet.

Step 3: Stainless Steel Hood Fabrication

The specialist begins manufacturing the hood according to the specific measurements of the kitchen.

Step 4: Installing the Fan and Duct

The fan is usually installed on the rooftop or an exterior wall.

Step 5: Final Testing and Air Balancing

The system is tested to ensure there are no unusual noises or air leaks.

Cost of Installing Commercial Kitchen Extraction Systems in Birmingham

The overall price depends on:

• Size of the hood

• Length of ductwork

• Type of fan

• Number of filters

• Complexity of the duct route

For pricing information, contact us here: Contact-Us

Maintenance and Servicing of Extraction Systems

- Washing the filters: every 7–14 days

- Servicing the fan: every 6 months

- Cleaning the duct: every 6–12 months

- Cleaning the hood: weekly

For full details, visit: The Best Time to Service and Maintain Your Restaurant Ventilation System

Why Is Choosing a Professional Company in Birmingham Important?

Some restaurants end up paying significantly more in the long run because they initially choose a cheap, unqualified company. The biggest misconception is thinking that extraction is “just a hood with a fan”, while in reality, the system affects:

- Passing or failing health inspections

- Increasing or decreasing sales due to indoor air quality

- Staff safety

- Monthly energy costs

Choosing an experienced company ensures:

Proper design, engineering drawings, airflow testing, and written warranty — all essential for professional restaurants.

Consultation for Choosing the Best Installation Company in Birmingham

To select a professional company, pay attention to:

- Experience in installing commercial hoods

- Use of high-quality materials

- Having real local projects in Birmingham that you can visit before installation

To see our team’s sample projects, visit: Service

Frequently Asked Questions

Do you need a permit to install a commercial extraction system in Birmingham?

In most cases, yes — especially if an external duct is being added. It’s best to coordinate with the local council beforehand.

For more information, click here: Do You Need Permission a Commercial Kitchen Hood in Birmingham

How often should grease filters be cleaned?

Usually every 1–2 weeks, but in heavy-duty kitchens, weekly cleaning is recommended.

Which fans are suitable for commercial extraction?

Centrifugal and backward-curved fans typically deliver the best performance.

How long does a full installation take?

Between one to three working days, depending on the size of the project.

Canopy

Canopy Fans

Fans Stainless Steel Sheets

Stainless Steel Sheets ESP

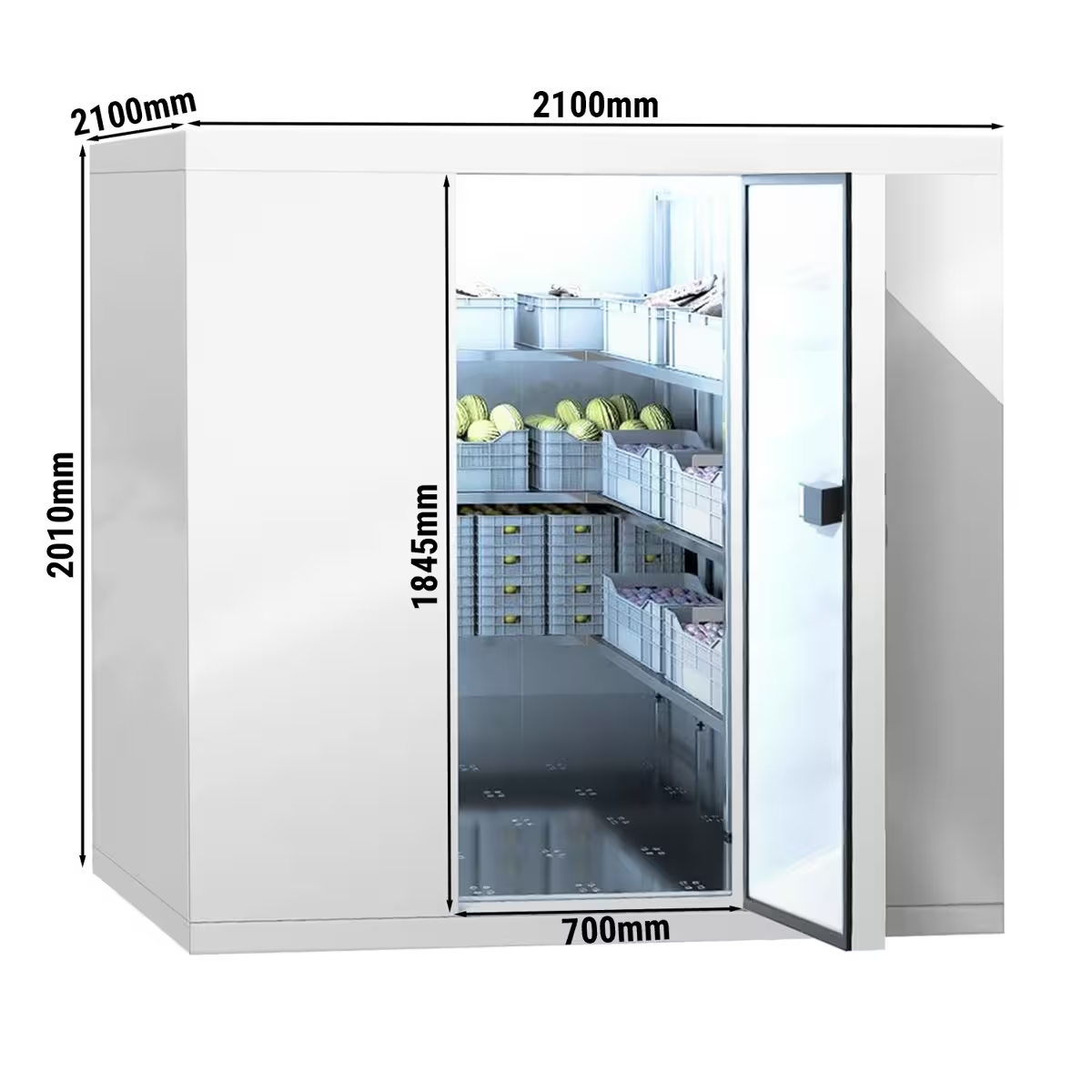

ESP Cold room

Cold room