The Difference Between Extraction Hoods and Filter Hoods in Commercial Kitchens

One of the most essential pieces of equipment required when setting up any commercial kitchen is the ventilation system — such as Extraction Hoods and Filter Hoods.

Due to the constant cooking that takes place in professional kitchens, large amounts of heat, smoke, steam, and grease are produced. Proper ventilation systems help prevent contamination and maintain a clean, safe environment.

In this article, we will explore the key differences between Extraction Hoods and Filter Hoods — two systems with distinct functions and applications.

What Is an Extraction Hood?

An Extraction Hood is designed to remove contaminated air from the kitchen environment.

This type of hood collects smoke, steam, grease particles, and heat produced during cooking and expels them outside the building through a network of ducts.

Extraction hoods are typically equipped with a powerful fan and a series of ducting channels. They are mainly used in restaurants, hotels, and large kitchens where heavy-duty cooking takes place.

Key Features:

- Completely removes polluted air from the kitchen.

- Requires ductwork and an external air outlet.

- Usually fitted with a grease filter to prevent contamination of the ducts.

- Ideal for large, high-volume professional kitchens.

Example of Use:

In a busy restaurant with several stoves and fryers running simultaneously, an extraction hood removes hot, greasy air, helping control the temperature and maintain a comfortable working environment.

What Is a Filter Hood?

Unlike an extraction hood, a Filter Hood does not expel air outside. Instead, it filters and recirculates the cleaned air back into the kitchen.

Air containing smoke and odours passes through multiple filters — typically a grease filter, activated carbon filter, and sometimes a HEPA filter — before being purified and returned to the room.

This system operates without ducts, making it an ideal solution for spaces where external ventilation is not possible, such as cafés, food trucks, or temporary kitchens.

Key Features:

- Filters and recirculates air back into the environment.

- Easy to install and requires no ducting.

- Filters must be replaced regularly.

- Suitable for small or temporary spaces.

Example of Use:

In a small coffee shop or an enclosed food stall, a filter hood maintains air quality without the need for external ductwork.

Main Differences Between Extraction and Filter Hoods

| Feature | Extraction Hood | Filter Hood |

| Airflow System | Expels contaminated air outside | Filters and recirculates air |

| Installation | Requires ducting and external outlet | Ductless and easy to install |

| Maintenance | Needs regular duct cleaning | Requires frequent filter replacement |

| Cost | Higher installation cost | Lower installation cost |

| Performance | Suitable for heavy-duty cooking | Limited efficiency with heavy smoke and grease |

| Energy Efficiency | May remove heat from the room | More energy-efficient as warm air is retained |

| Ideal Use | Large professional kitchens | Small or temporary spaces |

Advantages and Disadvantages of Each Type

Extraction Hood

Advantages:

- Completely removes smoke, heat, and odours.

- Meets strict hygiene and safety standards.

- Best suited for professional cooking environments.

Disadvantages:

- Costly installation requiring duct infrastructure.

- Ducts need periodic cleaning.

- May disrupt the temperature balance of the room.

Filter Hood

Advantages:

- Easy to install and portable.

- Lower overall cost compared to extraction systems.

- More energy-efficient.

Disadvantages:

- Limited ability to handle heavy smoke.

- Filters must be replaced regularly.

- May not meet commercial ventilation regulations in some areas.

How to Choose the Right Hood

Selecting the right hood depends on several factors — including the kitchen’s size, type of cooking, hygiene regulations, and budget.

- If your kitchen uses large stoves, fryers, or grills, an Extraction Hood is the best choice, as it completely removes grease and smoke, providing higher safety.

- If your space is small or lacks access for duct installation, a Filter Hood is a practical and cost-effective option.

Before purchasing or installing a hood, it is recommended to consult an industrial ventilation expert who can advise you on the best system based on your environment and local regulations.

Maintenance and Compliance Standards

Regular maintenance is essential for both types of hoods. Neglecting cleaning can lead to grease build-up, unpleasant odours, and even fire hazards.

- Extraction Hoods should be professionally cleaned every 3–6 months.

- Filter Hoods should have their filters replaced every 1–3 months, depending on usage.

Additionally, compliance with safety standards such as BS EN 16282 in the UK ensures your ventilation system meets hygiene and safety requirements.

Conclusion

Both Extraction and Filter Hoods play a crucial role in maintaining clean and safe air in commercial kitchens.

Their main difference lies in how they handle air — extraction hoods completely remove it, while filter hoods purify and recirculate it.

To make the right choice, consider the type of kitchen, level of cooking activity, local regulations, and available budget.

By choosing an appropriate ventilation system, you not only improve air quality and comfort but also enhance the overall efficiency and safety of your kitchen.

Canopy

Canopy Fans

Fans Stainless Steel Sheets

Stainless Steel Sheets ESP

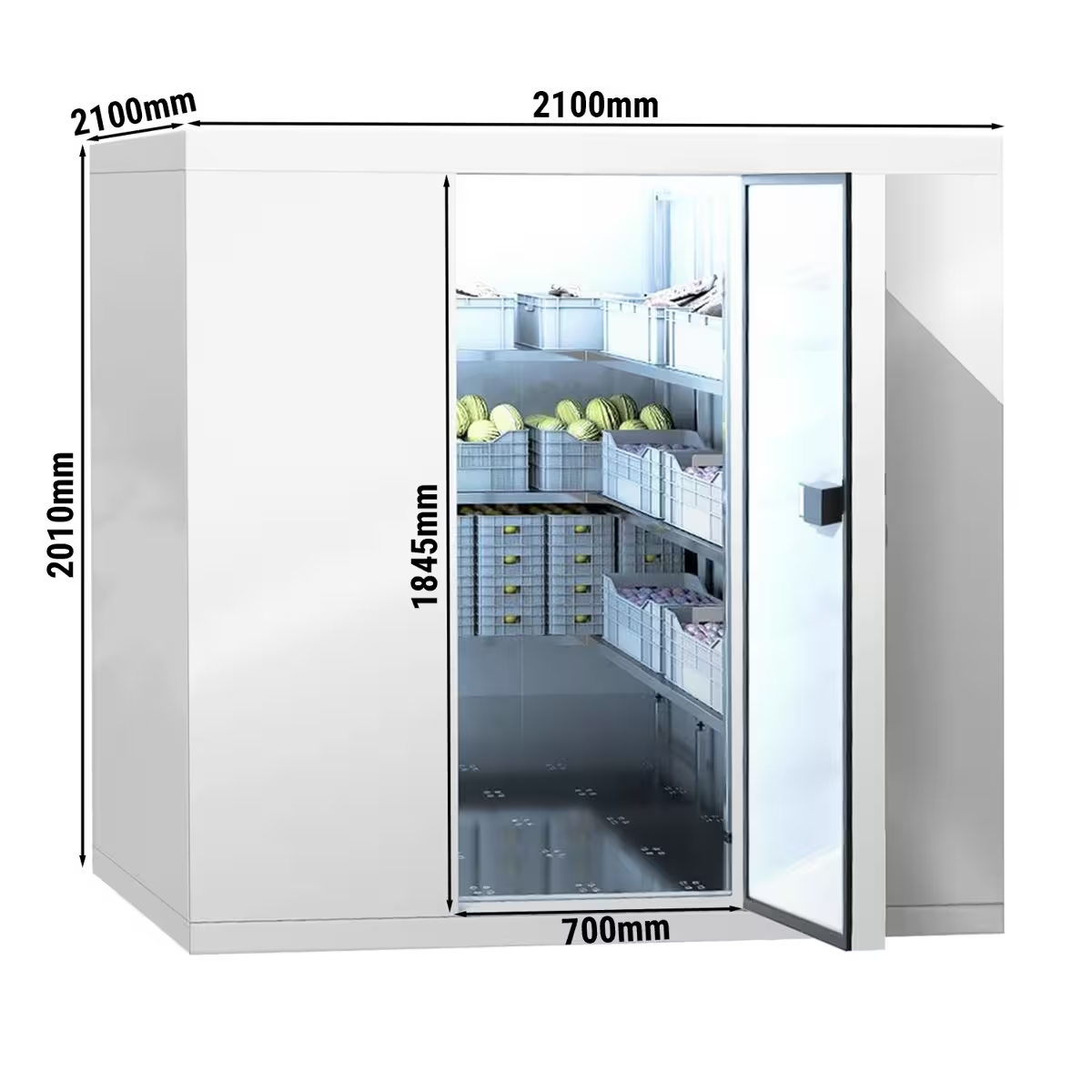

ESP Cold room

Cold room