Canopy

Canopy Fitting service

Fitting service Fans

Fans Stainless Steel Sheets

Stainless Steel Sheets Stainless Steel Tables

Stainless Steel Tables Stainless Steel Shelves

Stainless Steel Shelves Speed Controller

Speed Controller Ducting accessories

Ducting accessories

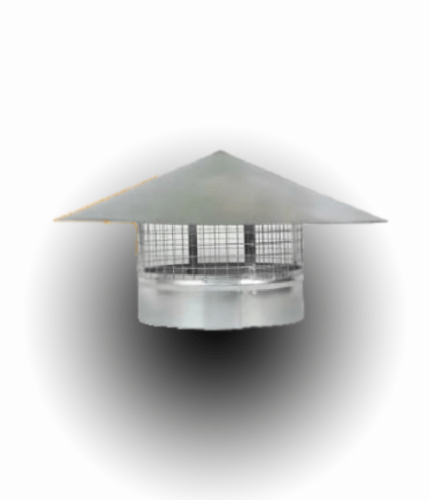

Weather Cowl

Weather Cowl Circular Duct |Spiral

Circular Duct |Spiral Silencer

Silencer Bend

Bend Carbon Box

Carbon Box Channel Slide Nuts

Channel Slide Nuts H-frame Foot Strut

H-frame Foot Strut Shoe Bend

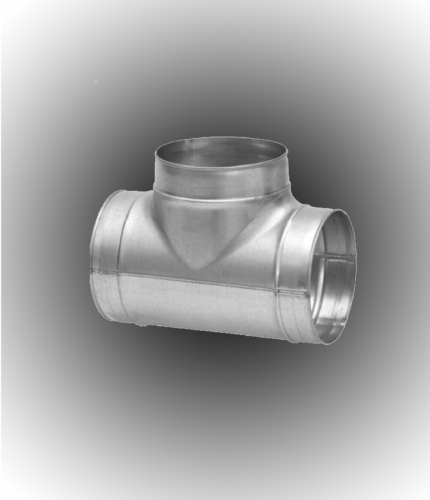

Shoe Bend Tbend

Tbend Twin Bend

Twin Bend Jet Cawl

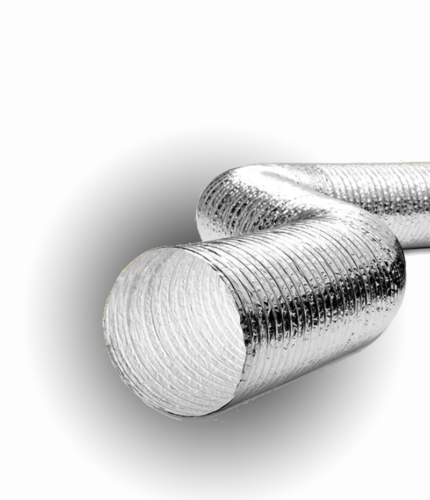

Jet Cawl Flexible Ducting

Flexible Ducting Pressed Saddle

Pressed Saddle Flanged Spigot

Flanged Spigot Spiral Duct Connecter

Spiral Duct Connecter Cap End

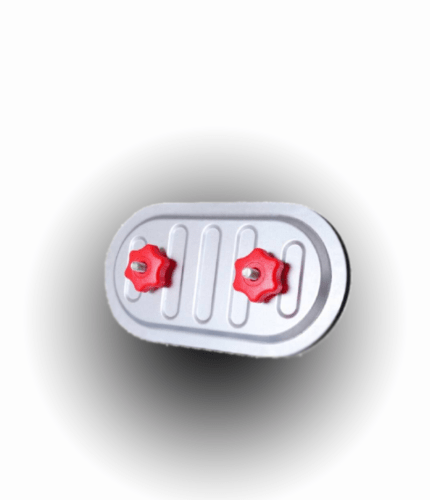

Cap End Access Doors

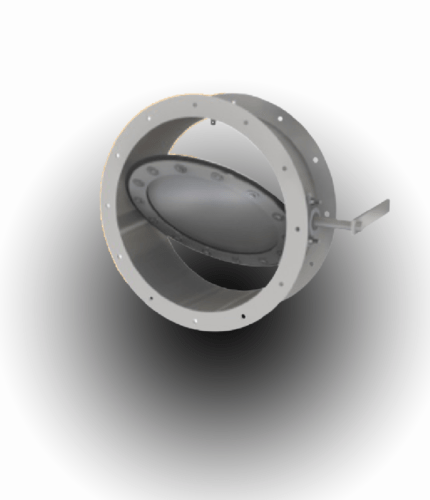

Access Doors Dampers

Dampers Flanging System

Flanging System Flashings

Flashings Grilles & Diffusers

Grilles & Diffusers Louves & Plenum Boxes

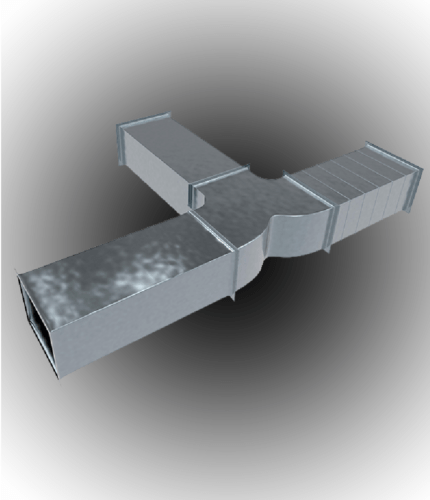

Louves & Plenum Boxes Rectangular Ductwork

Rectangular Ductwork

Ducting Fittings

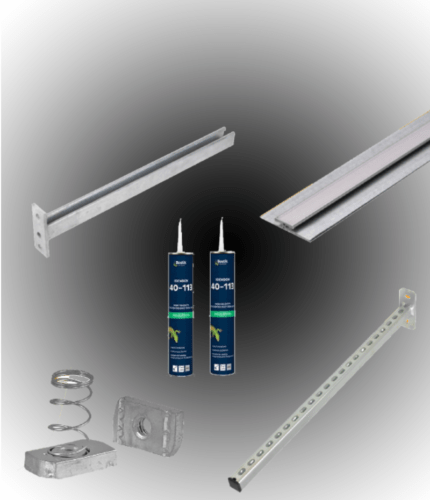

Ducting Fittings Sealants, Gaskets, Tapes & Insulation

Sealants, Gaskets, Tapes & Insulation

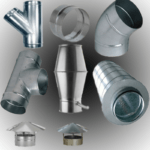

### Ducting & Fittings: What Are They and Why Are They Needed?

When constructing a ducting system, it is impossible to have only straight lines. Corners and connection points between ducts are inevitable, and these are achieved using ducting fittings. Depending on the type of ducting, corresponding fittings must be used.

#### Materials for Ducting Fittings:

- **Galvanized Steel**

- **Aluminium**

- **PVC/CPVC**

#### Sizes for Ducting Fittings:

Standard sizes include:

- 355mm

- 400mm

- 450mm

- 500mm

- 560mm

- 630mm

However, ducts are available from 63mm to 1250mm in diameter.

#### Types of Ducting:

- **Round**

- **Square**

- **Flat**

The exception to extensive use of fittings is **flex ducting**, which can bend around corners but still requires some connection points like grills or louvres.

#### Importance of Ducting Fittings:

Ducting fittings enable the connection of different sizes of ducts. For instance, you can connect a 150mm duct to a 120mm duct with a fitting designed for this purpose, which is crucial in system design. If you have a 120mm duct in the wall and need to connect it to a 100mm vent, a concentric reducer can facilitate this.

**Reducers** are particularly important when managing air volume. If a duct splits into two outlets, the remaining volume of air requires a smaller duct to maintain speed (measured in feet per minute, FPM). Using a reducer allows for continued airflow without losing efficiency.

#### Different Kinds of Duct Fittings and Their Applications:

**Bends:**

- Available in 30°, 45°, 60°, 90° angles.

- Used to change the direction of the ductwork.

**T-Pieces:**

- Available in 90° and 45° angles.

- Used to split a single duct from the main one, with various sizes available.

**Y-Pieces:**

- Used to split a single duct into two at a 45° angle.

- Sizes range from 80mm to 710mm wide.

**Connectors:**

- Used to connect ducts, available in male or female versions, depending on whether they go inside or around the duct.

**Caps:**

- Used to seal the end of a duct.

**Bird Beaks:**

- Installed when ducts point outside a wall, featuring a metal mesh to prevent birds from nesting.

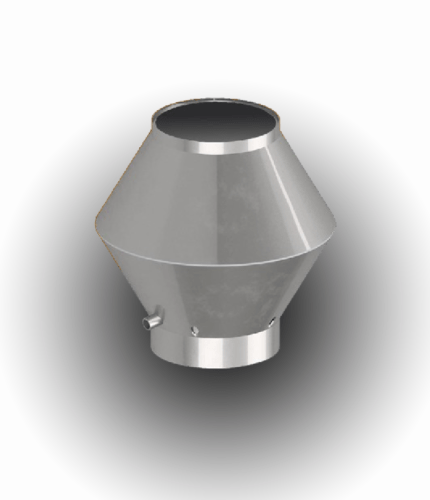

**Weather Cowls:**

- Used for ducts pointing out from a ceiling to prevent water and snow ingress.

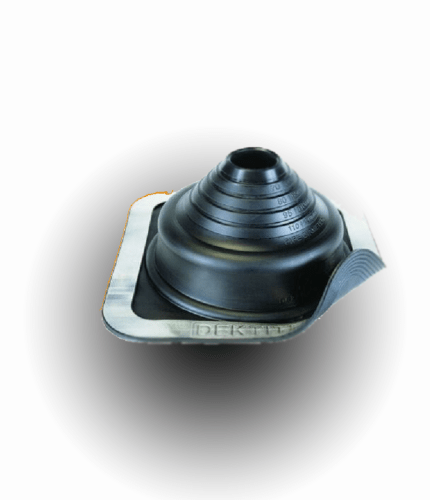

**Dektites:**

- Provide a watertight and weatherproof seal around the pipe.

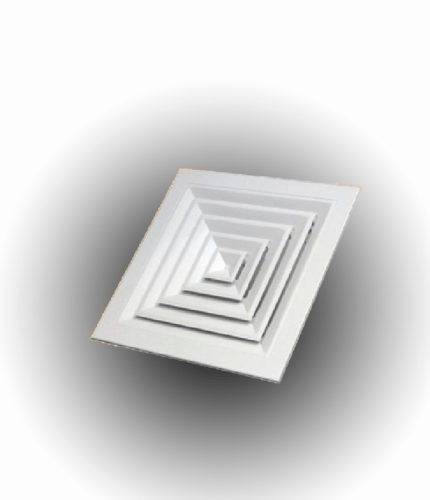

**Grilles and Louvres:**

- Serve as visible end-points from inside the facility.

**Additional Fittings:**

- **Collars, Flat Shoes, Curved Boots, Flanges, Clips, Access Doors**

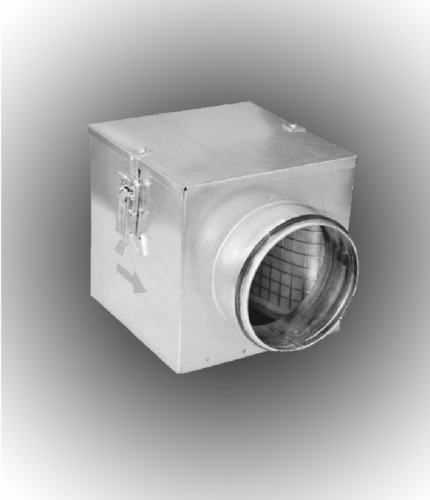

- **Inline Heaters and Filters:** Provide heating or air filtration.

- **Dampers:** Control airflow to prevent excessive force from blowing out the vents.

These fittings are integral to any duct system to meet regulations regarding flow speed and air volume. Even without regulatory obligations, optimal HVAC performance depends on appropriate fittings.

At [CanopyMan.uk](https://canopyman.uk), we specialise in the production and installation of industrial hoods and ducting systems for commercial kitchens. Our expertise ensures that your HVAC systems function efficiently and comply with all relevant standards.

Canopy

Canopy Fitting service

Fitting service Fans

Fans Stainless Steel Sheets

Stainless Steel Sheets Stainless Steel Tables

Stainless Steel Tables Stainless Steel Shelves

Stainless Steel Shelves Speed Controller

Speed Controller Ducting accessories

Ducting accessories Weather Cowl

Weather Cowl Circular Duct |Spiral

Circular Duct |Spiral Silencer

Silencer Bend

Bend Carbon Box

Carbon Box Channel Slide Nuts

Channel Slide Nuts H-frame Foot Strut

H-frame Foot Strut Shoe Bend

Shoe Bend Tbend

Tbend Twin Bend

Twin Bend Jet Cawl

Jet Cawl Flexible Ducting

Flexible Ducting Pressed Saddle

Pressed Saddle Flanged Spigot

Flanged Spigot Spiral Duct Connecter

Spiral Duct Connecter Cap End

Cap End Access Doors

Access Doors Dampers

Dampers Flanging System

Flanging System Flashings

Flashings Grilles & Diffusers

Grilles & Diffusers Louves & Plenum Boxes

Louves & Plenum Boxes Rectangular Ductwork

Rectangular Ductwork Ducting Fittings

Ducting Fittings Sealants, Gaskets, Tapes & Insulation

Sealants, Gaskets, Tapes & Insulation